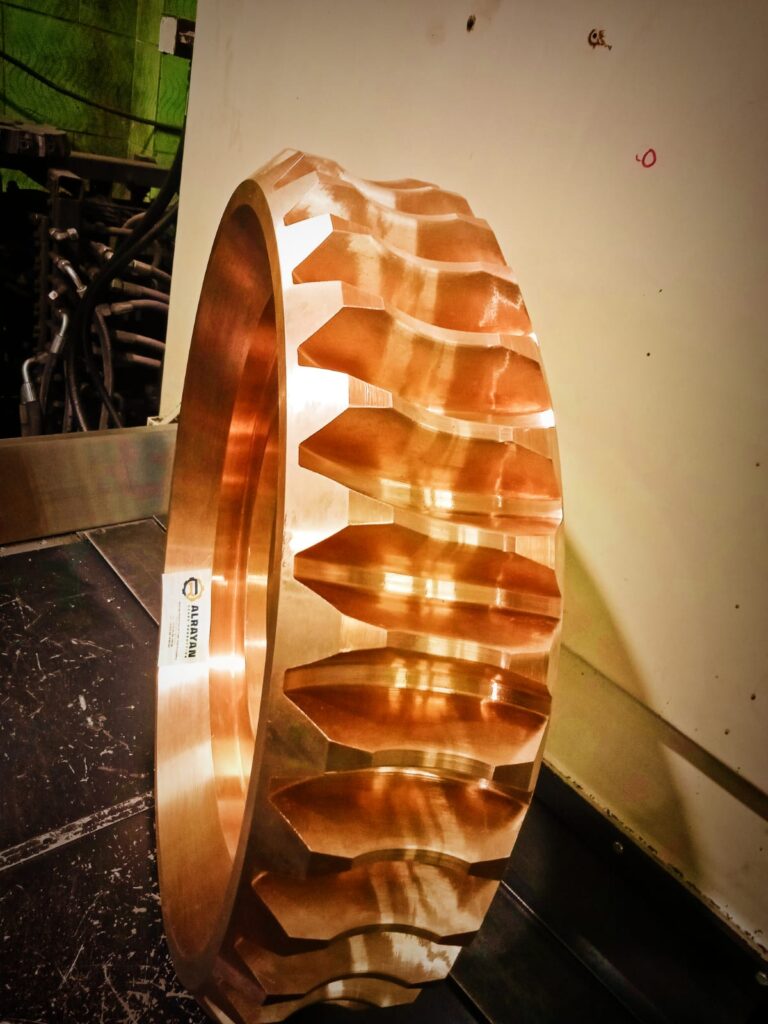

Worm Gears Manufacturing

Our worm gears manufacturing process combines precision engineering with advanced technology. Recognized for their screw-like design, worm gears are vital for applications requiring high torque and smooth, quiet operation. We start with high-quality raw materials, ensuring durability and performance. Using state-of-the-art CNC (Computer Numerical Control) machinery, we achieve precise tooth profiles and dimensions, essential for optimal performance. Each gear undergoes stringent quality control checks to meet our high standards, providing reliable and efficient solutions for mechanical systems.

Our dedication to innovation and excellence drives us to continuously refine our manufacturing techniques. We use advanced heat treatment processes to enhance the strength and wear resistance of our worm gears, making them suitable for demanding applications across various industries, including automotive, aerospace, and heavy machinery. By leveraging cutting-edge technology and skilled craftsmanship, we ensure our worm gears deliver exceptional performance and longevity. At Mass Gear, we are committed to providing high-quality products that meet specific client needs and exceed expectations, ensuring optimal performance and reliability in all applications.

Mass Gears For Mass Industries